Rotational Molding is an age old manufacturing process in which a hollow mold is filled with softened material and rotated in order to disperse the material evenly within the mold to produce a hollow part. Humans come into contact with, and often use a variety of Rotationally Molded products many times over the course of a single day. Materials can range from Plastics, Waxes, Metals and even Chocolate. Depending on the end products, Rotational Molding Machines can be very small, or very large, and often require large sprockets to rotate the molds. Sometimes these sprockets are repurposed for other uses, which requires extensive manufacturing, and this is where Owen Industries comes in.

Sprocket Lightening is a term used when material is removed from an original sprocket in order to reduce its overall weight. This adds processing benefits down the line, such as customization and reduced costs to operate. MVS Metals was recently presented with the task of removing via Water Jet the Central Hub and (4) Lightening Slots from a 4” thick x 7-1/2’ Outside Diameter 7,000# Sprocket used on a large Rotational Molding Machine. An operation of this magnitude certainly does not come without its own unique set of challenges.

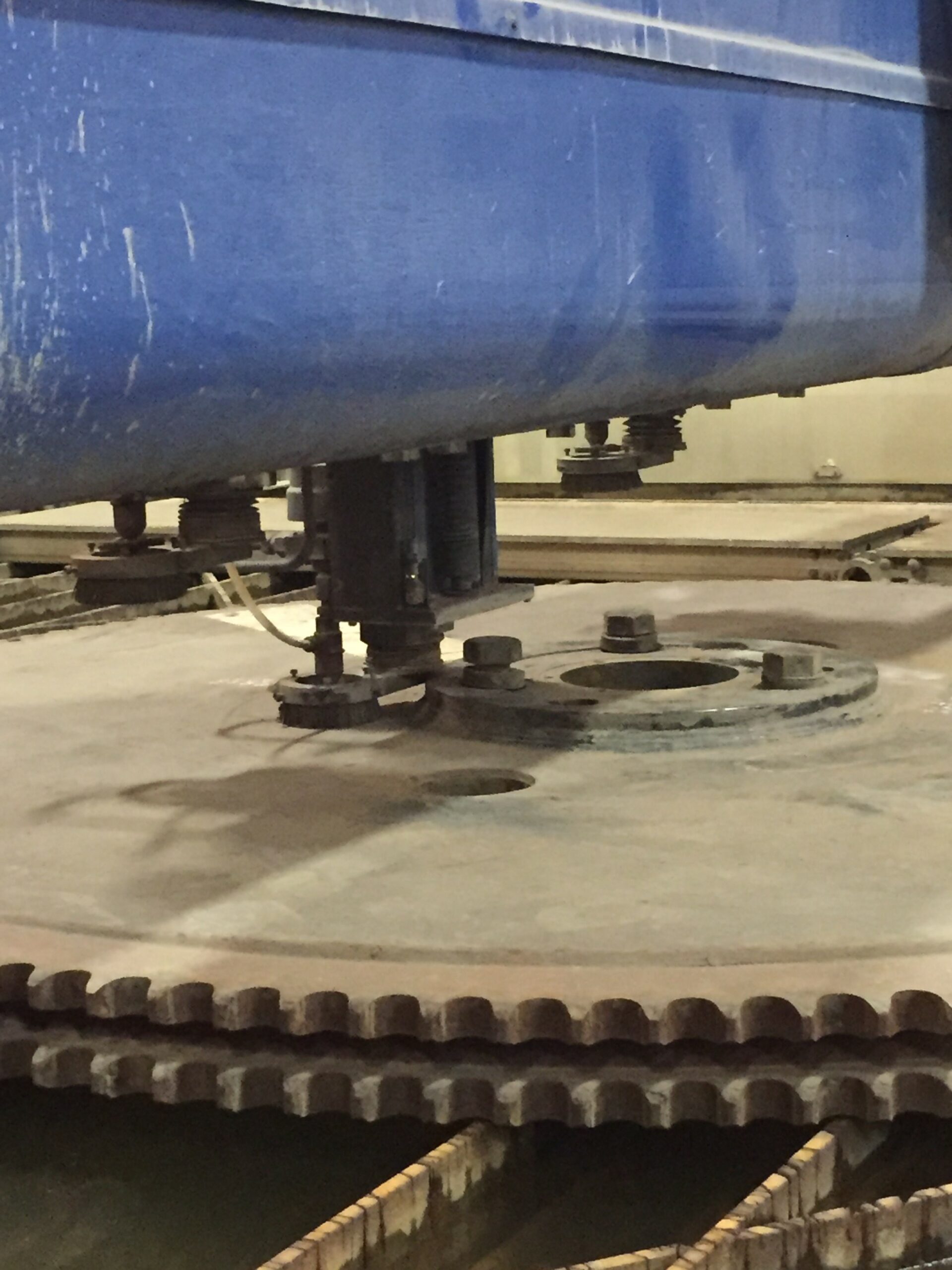

The biggest hurdle was a contact issue between the Hub Shoulder and the Boot Housing on the Water Jet Cutting Torch. This challenge was overcome with an Air Arcing procedure used to remove material from the Hub Shoulder to allow the Boot Housing to pass freely around the Hub. Because the central Hub was being replaced with a new Rotational Fitting, MVS Metals was given the green light to modify the existing Hub. Once completed, the rest of the cutting process went off without a hitch.

Overall processing time was slightly over 40 hours with a cutting speed of a little over 3/16” per minute. Our speed and abrasion combination achieved a quality cut and a very aesthetically pleasing finished part. MVS Metals reduced the original Sprocket weight by about 44%, and helped give new life to a renowned piece of manufacturing history. If you have a similar project, or any project that you would like some professional manufacturing input, please feel free to contact us at Owen Industries!