Many of the manufacturing sectors best customers choose to do business with Owen Industries, not only because of our competitive pricing and quality of work, but by our dedication to the services we can provide.

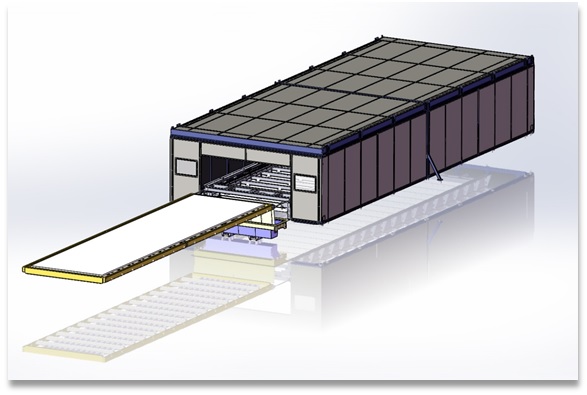

We like to paint our boundaries with a broad brush, and with the upcoming installation of the largest standalone Fiber Laser Shuttle System in the country, we will be doing just that.

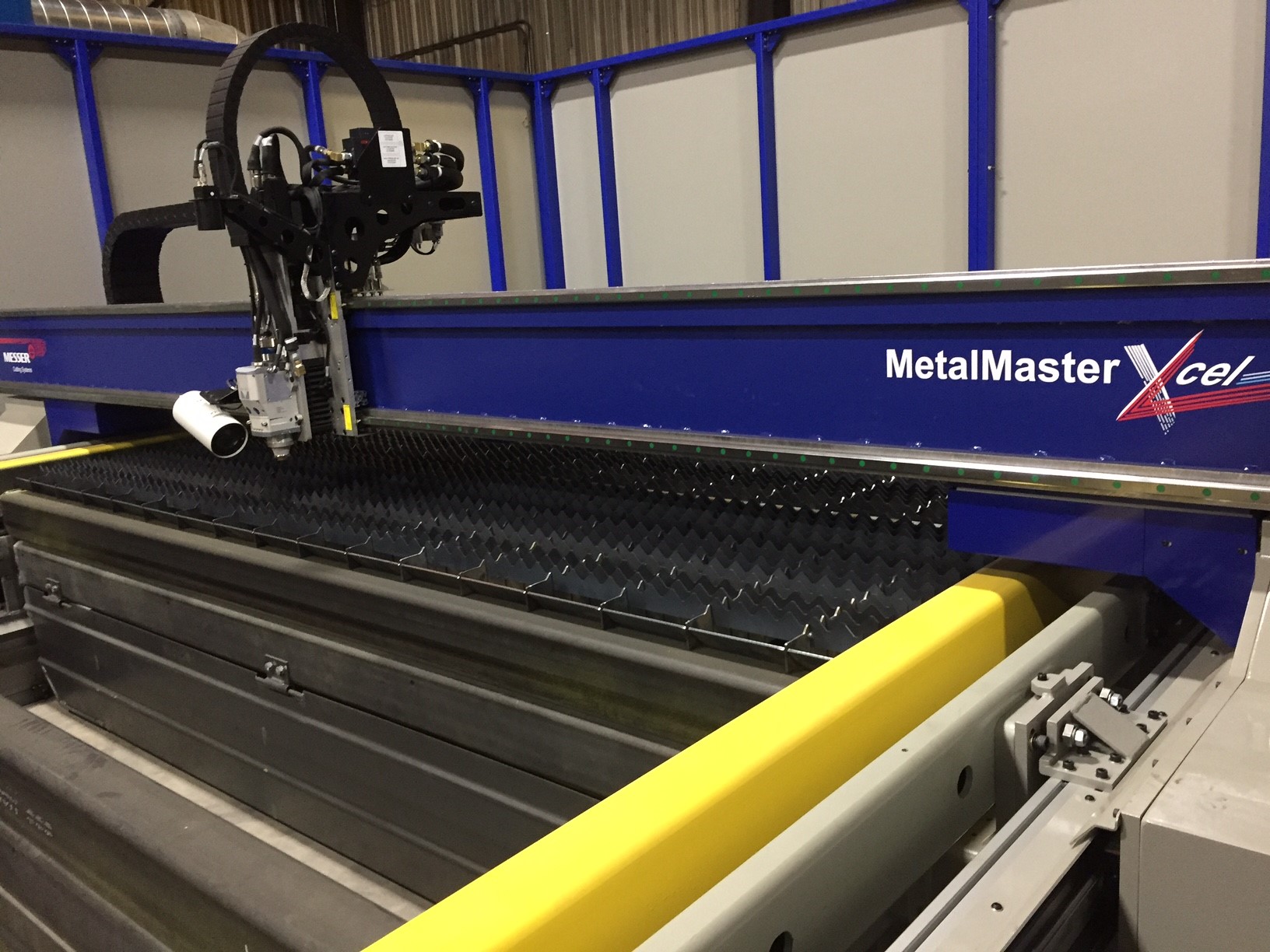

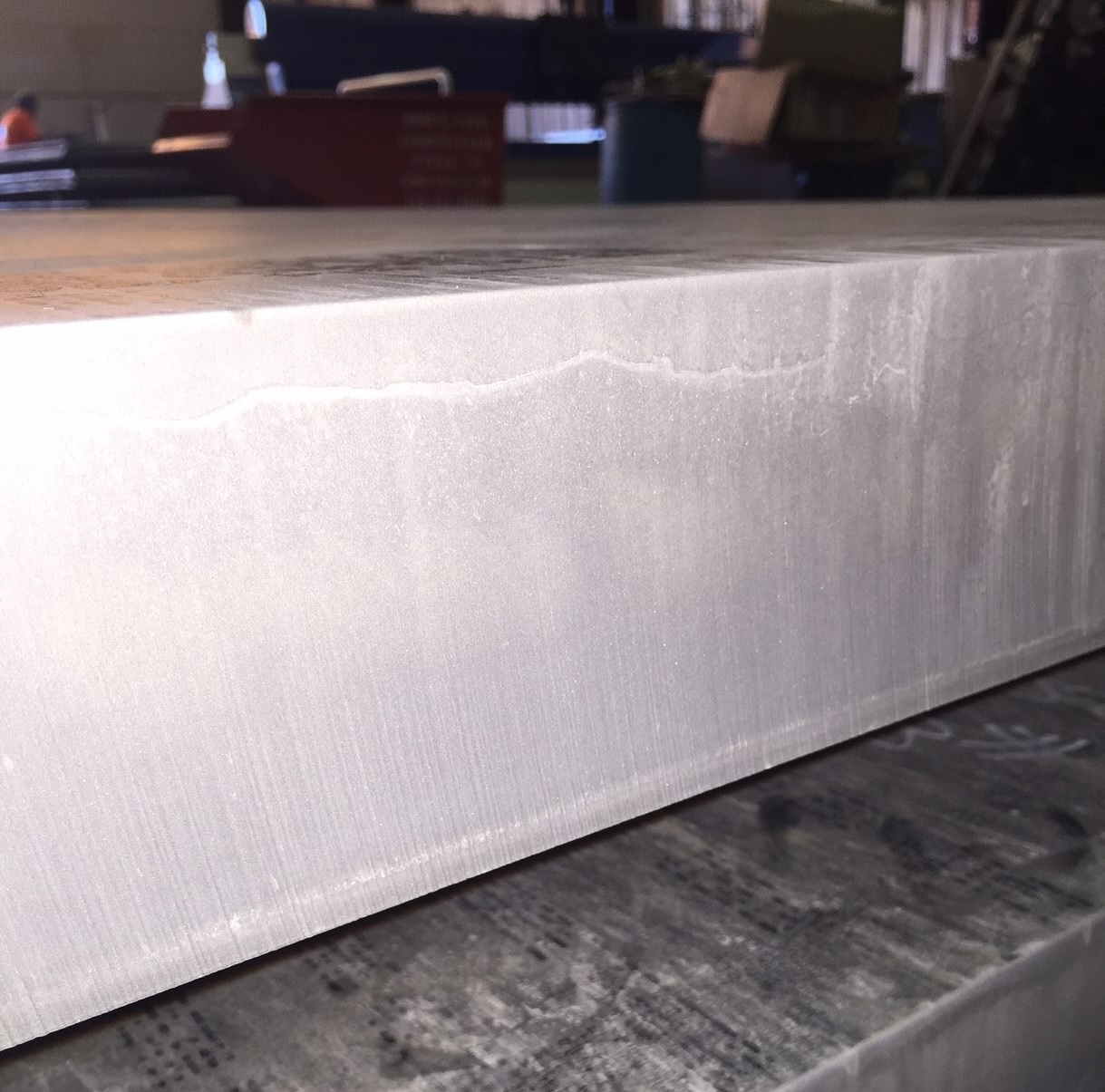

Topped with a Messer YLS Series 6000 Watt Fiber Laser capable of cutting stainless, aluminum, titanium, brass, copper and mild steels, our 10’-0” x 40’-0” shuttle bed system can simultaneously process up to eight (8) standard sized 5’ x 10’ sheets at a time. Combined with one of the world’s largest Red Bud Stretcher-Levelers, we can now supply and process via fiber laser our own material, up to 1” mild steel at 40’-0” long.

Owen Industries chooses to continuously improve our product service repertoire so that you, our customer or future client, can expand your reach into the market, instill quality service and build excellent business relationships.

Please contact Aaron Mousel at amousel@mvsteel.com at your convenience. We are scheduled to go online January 2017, so don’t wait to get your quotes in today!