Northern Plains Finishing celebrated their 10-year anniversary in Casselton, ND. on Friday, June 16th, 2023. The event hosted customers, employees, and city leaders. The first parts were coated in October 2013 and business has grown 400% from those humble beginnings. All things are possible with great employees, customers and owners that are willing to make the investments to facilitate our needs. We are excited to see what the next 10 years will bring to NPF and Owen Metals Group!

NPF Finishing

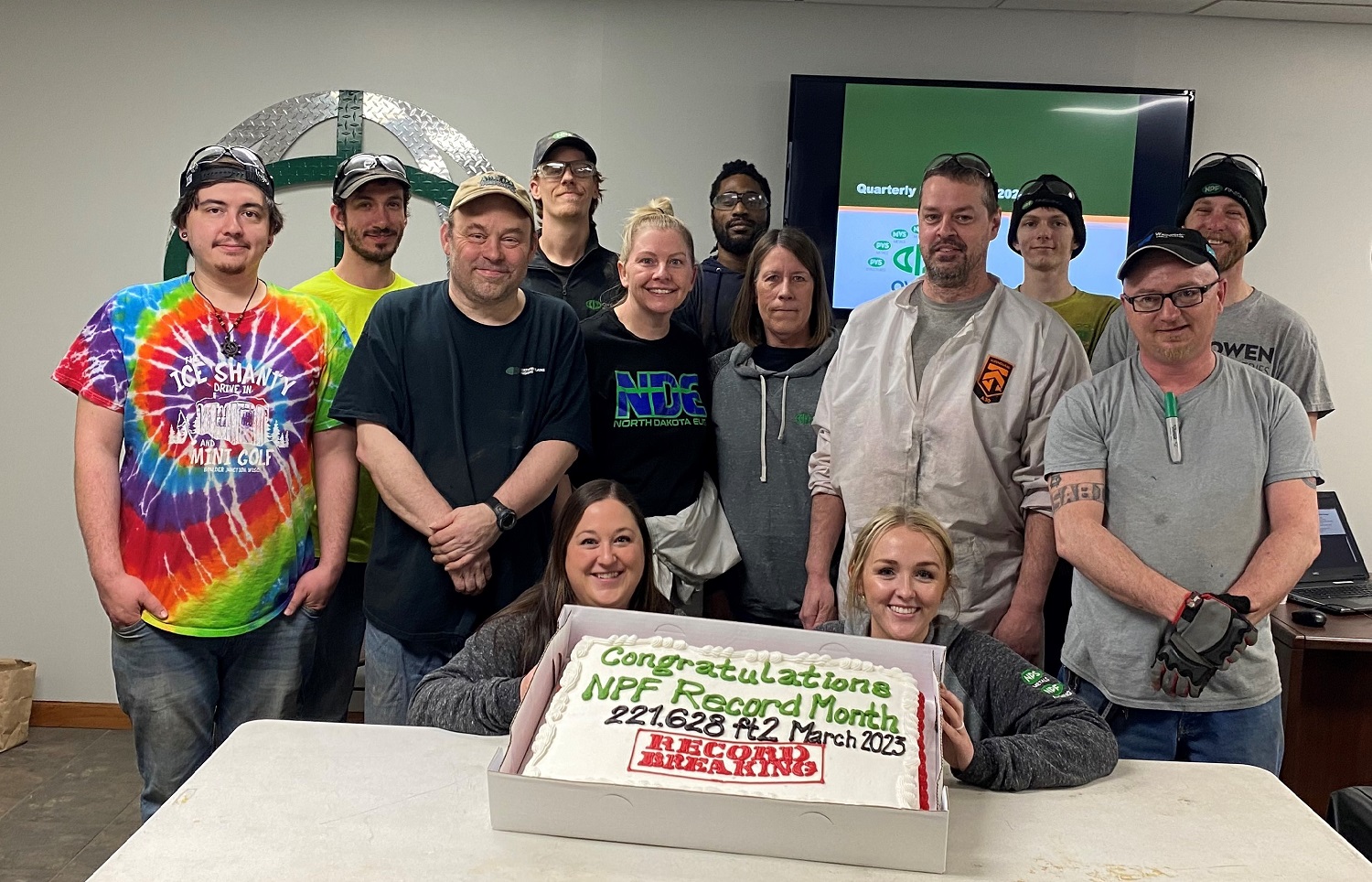

NPF Finishing Sets Record-Breaking Month!

NPF Finishing had a record-breaking month in March with 221,628 square footage of parts painted. Great job to our team out at NPF!!

NPS Metals, NPS Finishing and Owen are happy to be a part of the American Heart Association – Fargo Heart Walk! There were lots of walkers, great survivors and really cool media. This sponsorship funds local heart and stroke research in the Fargo area.

On Saturday, February 26th our Owen Metals Group employees from the NPS Division participated in the Polar Plunge benefitting the Boys and Girls Club of Detroit Lakes, Minnesota.

Owen and the group donated $680.00 to the cause and the total contributions exceeded $57,000.00.

Plunging into the lake were: Craig Larson, Brian Riskey, Quinn Harmon and Mark Radtke.

Mark Radtke, our Vice President and General Manager of NPS/NPF recently celebrated 40 years of service. We sat down with Mark to ask him a few questions on his tenure here.

During your 40 yrs. of tenure, how has the business evolved, types of products, customers / industries served, technology?

- When I began my role at NPS we were a very small (16 person) organization. Our customer base was predominantly Ag based and we were a more localized business than we are now. We currently ship worldwide and have numerous world class customers that are in every type of manufacturing imaginable. When I started with NPS in Inside Sales we had no computers on our desks, all the order entry was done by hand, production orders were released by hand and all prints were drawn by hand, full size. We handled a full line of steel, plate, sheets, tube, flats and even some rebar. We had one press brake, a shear, a flame cutter, a bandsaw and a huge amount of unused space. Imagine a shop without lasers, OPTS, forklifts running around or nesting. Our sales are now 20 times what they were back in the early 80’s and technology has been the major driver in the growth. I have always been more interested in growing the processing side of the business as selling just raw materials seemed simply boring to me.

Do you have accomplishments that you’d care to mention, which you are most proud of here at NPS/NPF?

- Our long-term dedicated employees, the start-up of NPF, automation at NPS and having a solid succession plan.

What advice would you give to our new hire employees as it relates to growing within the business and succeeding as you have from your humble beginnings all the way up the ladder to the GM position?

- Come to work on time, treat your co-workers with respect and do your best each day. Study and develop new processes and remember that small improvements over longs period of time moves mountains. Management does see when you go the extra mile and it will pay off in the long term.

What is your vision for NPS/NPF for the next 40-yrs? What changes / opportunities do you foresee in the industry if any?

- To grow and be viable, we will need to continue to purchase advanced, highly-automated machines. Many shop floor processes will need to be to run and monitored remotely as the landscape of the new employee is to work from any location, at any time. To attract and retain the best employees, improved process flows and employee participation rates will be closely monitored as this will evolve as the major role in measuring each employee’s value, success and pay rate.

Thank you Mark, for all you do to make us better!

Congratulations to Doug Brennan for his 35 years of Service at NPS Metals a division of Owen Industries. Doug is currently the Quality Manger for both NPS Metals and NPF Finishing. He started his career running various machines from Press Brake, Flame Cutter, to Welding. He then became a driver operating one of our semi-trucks to deliver parts to customers. When NPS got their very first laser in 1996, Doug became the very first Laser Operator for the division at that time. He ran the laser until 2002 when he moved into his current role as Quality Manager and has worked in that role since then.

Congratulations on 40 years of service to Steve Gunderson at Owen Industries. Over the years Steve, “Gunner” as he likes to be called, has had the privilege to work for three generations of the Owen family; Ed, Bob, and now Tyler. During his time with the company Steve has had the opportunity to work in several different positions operating a wide variety of machinery. Steve has worked from Shearing, Crane Operator, Sawing, Press Brake, Side Stacker to Shipping Supervisor. He is a member of the safety committee, steering committee, and is a certified quality auditor.